The slippery story of PTFE

Urban myth says that the material in the non-stick frying pan was a result of US space research, but it’s not. It was invented long before this by a friend of mine, a trombone-playing chemist called Malcolm Renfrew, in 1946 (before I was born). Malcolm also invented the acrylic polymer used by dentists to seal teeth which is set by UV light. He lived to be a hundred in 2010 and I was surprised to find that a little shop had a choice of birthday cards of that age. He remarked that it was unheard of in his younger age, but the efforts of chemists and chemical engineers had given so much to medicine that centenarians had become common enough to market to. But enough about us.

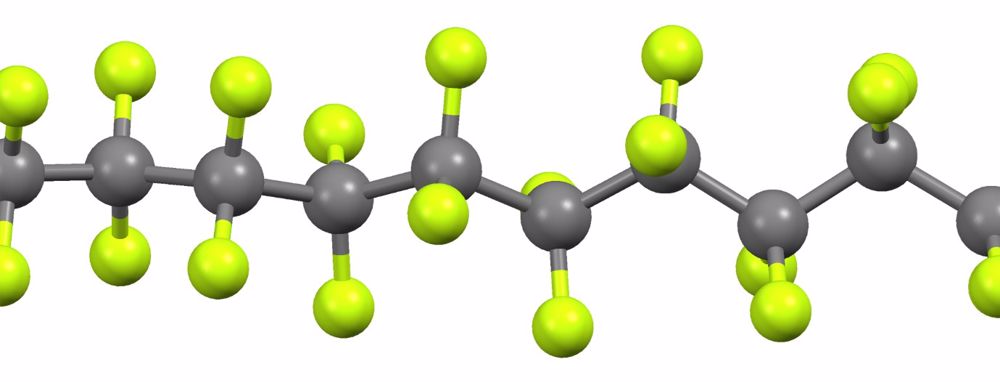

PTFE is poly(tetrafluorethylene) as polythene is poly(ethylene). Ethylene is CH2=CH2. Tetrafluorethylene is CF2=CF2, just replacing the hydrogens with fluorine atoms.

When polymerized they make a chain of carbon atoms (shown grey here) surrounded by the other element. If the chain is short, the polymer is a liquid. The longer it is, the more solid it becomes.

The trick is to make the chains the right length for what you want.

In 1938 a chemist called Roy Plunkett was trying to make tetrafluorethylene gas as a refrigerant, but found some wax inside the cylinder as the gas had partially polymerized. It took some years and Malcolm Renfrew to come up with an industrial method giving the right chain length, trademarked as Teflon by his company DuPont.

Fluorine is extremely reactive. A consequence is that once reacted, it is hard to shift so PTFE is chemically extremely resistant. It was helpful as a protective coating in industry using some of the most corrosive materials, including the process for uranium enrichment. It is also extremely slippery, and the Guinness Book of Records gave it the record for the slipperiest solid, which it held until 1995, so had lots of uses in mechanical engineering.

In France in 1954, engineer Marc Grégoire used PTFE to coat his fishing tackle to make it easier to clean. His wife Colette demanded he use it to coat a frying pan. It took some work to make this non-sticky plastic adhere to metal in a hot pan, but in 1956 Colette and Marc had them in the shops. The name was Tefal from Teflon and aluminium.

In 1961 an American inventor produced his own version on cast iron, and the urban myth began that it was a coating for rockets. But that is not the end of the story.

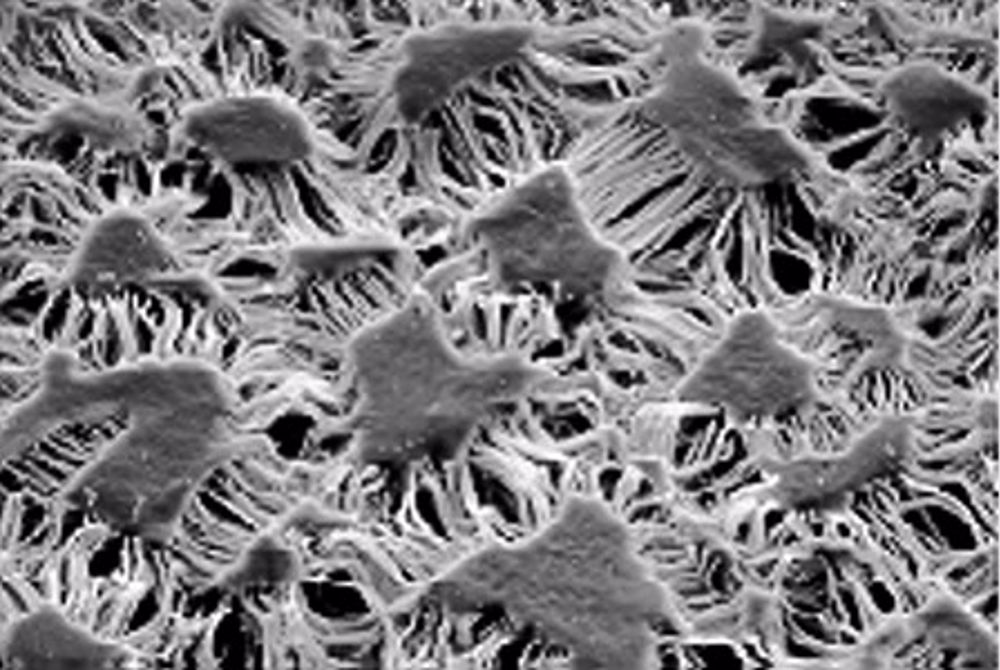

In 1957, one of DuPont’s chemical engineers, Bill Gore, left the company to set up a business with his wife Genevieve making ribbon cables for computers insulated with PTFE. In 1969 his son Bob Gore (also a chemical engineer) was working to find the ideal conditions of heat and tension for stretching rods of PTFE in processing. In frustration he yanked it hard by hand, and it stretched about eight times. It also opened up, becoming porous.

Instead of regarding this as a failure, their inventive minds looked for applications as they developed the practical production process. The material was given the trademark Gore-Tex. The most famous application is its use as a waterproof membrane in clothing which still allows the passage of water vapour so does not become sweaty.

There are, of course many other applications and inventive uses.