Aspdin’s Patent Powder - Cement

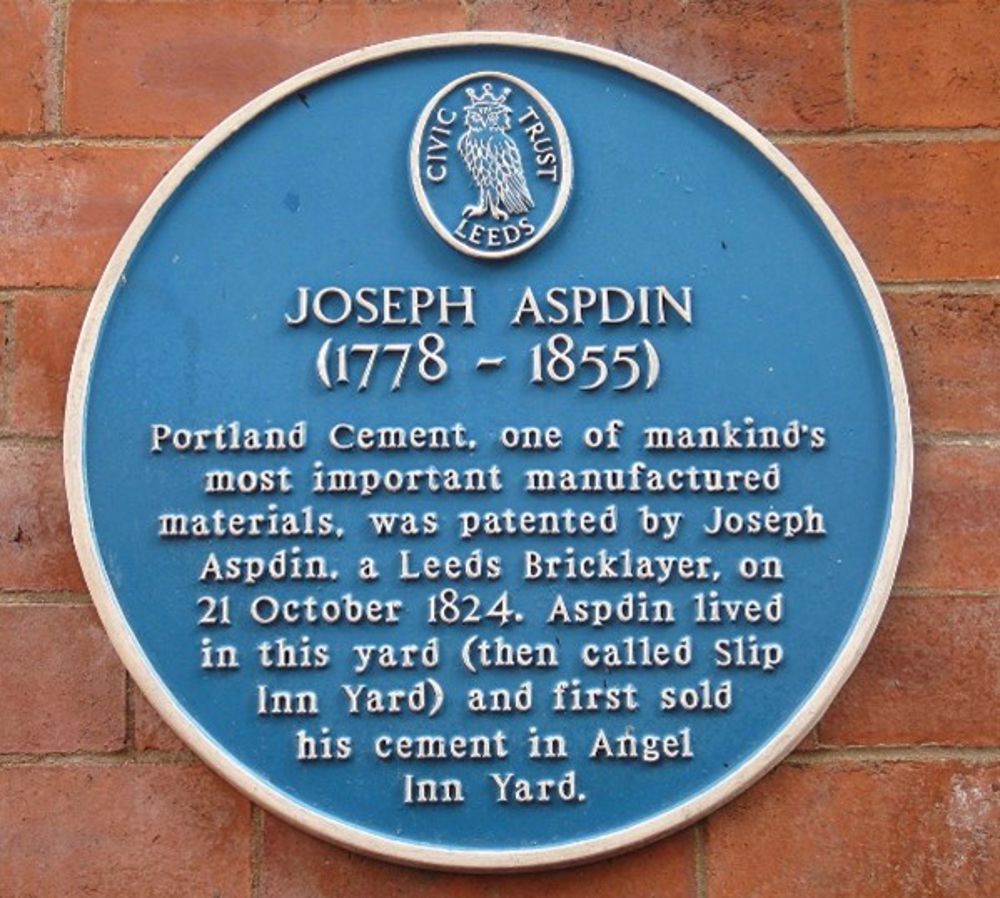

Few people have heard of Joseph Aspdin, yet his chemical invention was critical for modern society.

In 1824 Aspdin patented Portland Cement. A powder which reacted with water to make something like the finest Portland stone in any shape, much easier and cheaper than carving. Today concrete made from it is the material which is most used in the world, second only to water.

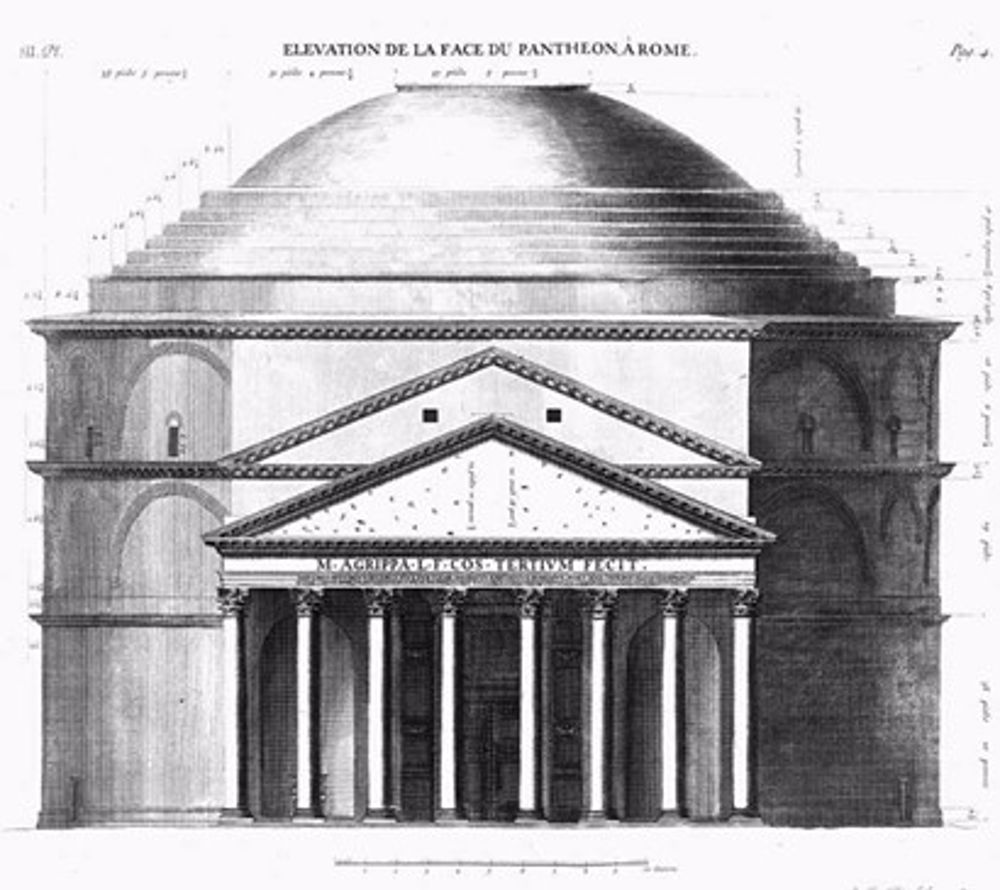

He was not the inventor of cement – that honour goes to the Romans about 2000 years before. The word cement is Latin, as is the word concrete (meaning with stones) and mortar. Roman cement is durable. The largest free-standing unreinforced concrete dome in the world today is still the 43 m diameter one on the Pantheon Temple in Rome, constructed about 126 AD.

The Romans carried out many chemical engineering processes. In this one, limestone (calcium carbonate CaCO3) was heated (1000 °C) to drive off the CO2 to make quicklime (CaO). This had many uses. Treated with water it would slowly absorb CO2 from the air to go back to limestone. Mixed with sand it was used as mortar between the bricks and stones of their buildings. To make their cement, it was mixed with volcanic ash and water. The ash was not just a filler, but reacted, and slowly set.

Roman cement faded with the empire, but lime burning to make mortar continued. After a lot of experimentation Aspdin did something new.

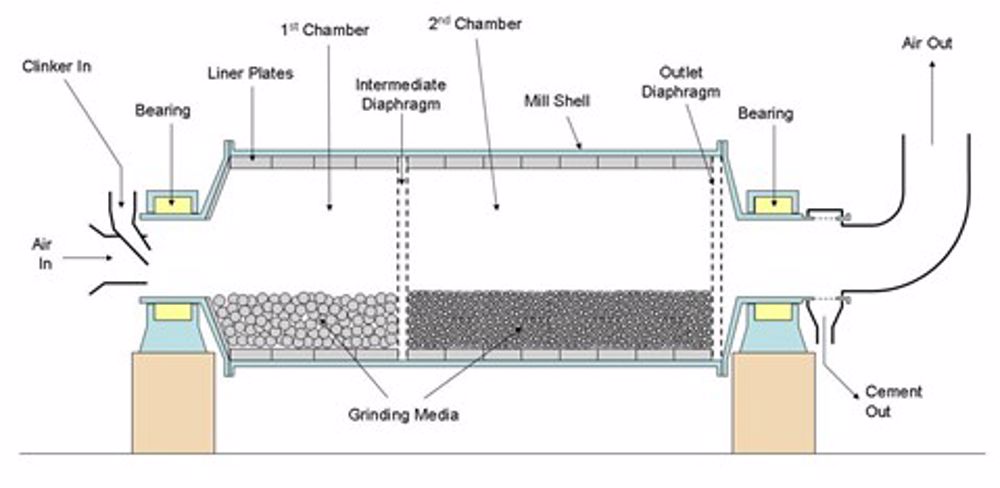

Having made the quicklime, he mixed it with clay and heated the mixture again (1700 °C) to convert the clay into his new material (known as double burning). Unlike the Romans’ cement it was not a mixture because the lime and clay ash had joined together chemically and melted into lumps called clinker. These were ground up to make his special powder. It also did not depend upon CO2, just water which chemically reacts, joining molecules together in what is an inorganic polymer. Nor did it need volcanic ash, but could be produced from minerals quarried in Leeds where Aspdin lived. He used coal for heating from mines nearby.

(A material incorrectly called Roman cement had been produced earlier, by single burning of some mineral which contained both limestone and clay, but the mixture was rarer and the composition uncontrolled.)

Aspdin’s product was much better than lime mortars and much quicker to set than the Romans’ cement. So fast, in fact, that a little gypsum is added to slow it down. His son William converted his invention into an industry with many producers.

There have been many technical developments and of course reinforced and pre-stressed concrete make use of the complementary properties of steel. However, the chemical process which makes it and the chemical reaction by which it sets are still much the same. The crushing, grinding, mixing and heating are all chemical engineering processes, and chemical engineers design and run such plant. Aspdin used a batch process with two heating stages, but modern cement works combine them in a continuous process.