Systematic Water System Design with Process Integration

Process integration was originally developed for energy recovery system in mid-1970s. In mid-1990s, process integration was extended to address industrial water recovery system, with the introduction of water pinch analysis by Professor Robin Smith at the University of Manchester in his seminal paper (Wang and Smith, 1994). The technique is based on the targeting philosophy of process integration, where system targets, i.e. minimum fresh water and wastewater flowrates are identified ahead of detailed design. Performing this water minimisation initiative leads to reduced water consumption and lower operating cost of the process plants.

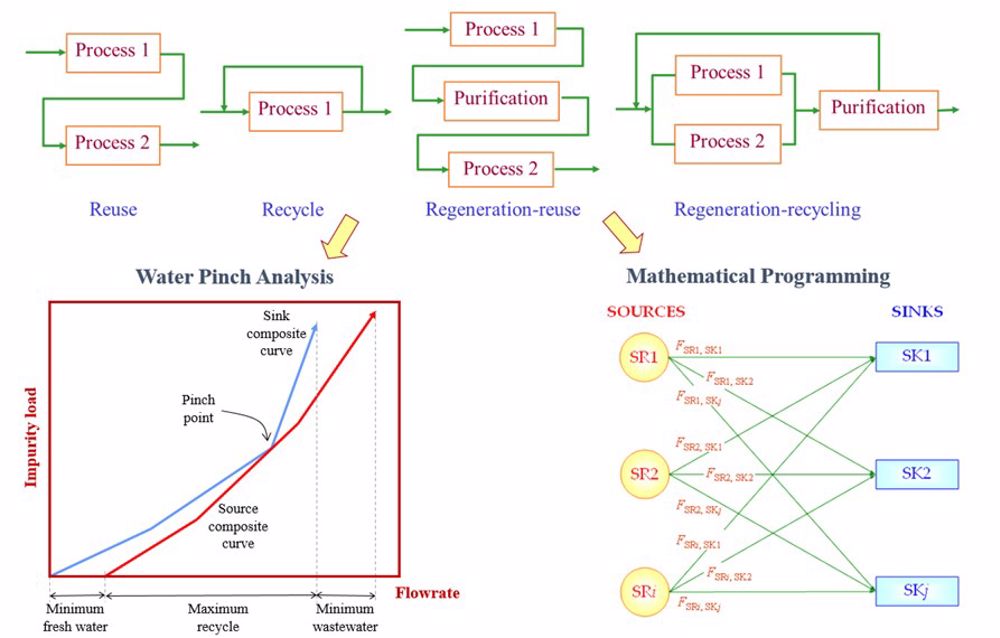

In principles, four water recovery schemes may be implemented. Water reuse refers to the recovery scheme where wastewater from a process is channelled to another unit and does not re-enter the unit where it is generated; this restriction is lifted for water recycle scheme (Wang and Smith, 1994). The first priority among these scheme is always direct reuse/recycle, as it involves lowest expenditure. When the maximum potential for direct reuse/recycle is exhausted, the waste material may be sent for regeneration in a purification unit where its impurity is partially removed; this allows further water reuse or recycle.

Apart from water pinch analysis, mathematical programming techniques have also been developed to address water minimisation problems. Both techniques have their advantages and limitations. Pinch analysis techniques allow water saving targets to be identified ahead of detailed design, but is limited to single contaminant cases. Mathematical programming on the other hand, is able to handle multiple contaminant problems, along with complex network cases and cost optimisation, though it suffers from the lack of providing good insights for process designers. Hence, pinch analysis and mathematical programming techniques complement each other well in solving various industrial problems. There are also hybrid techniques that make use of both water pinch analysis and mathematical programming techniques in order to overcome the limitations of the individual techniques.

Apart from continuous operations, water minimisation for batch processes were also being addressed (Majozi, 2010; Foo, 2012). This is particularly important for industries such as food and beverage, polymer and biochemical production. In most cases, water storage facilities and scheduling are to be synthesis for an optimum water minimisation scheme.

After more than two decades of development, process integration techniques for water minimisation are relatively mature. A compilation of these techniques may be found in review papers (Foo, 2009; Gouws, 2010) and textbooks (Majozi, 2010; Foo, 2012; Smith, 2016; El-Halwagi, 2017). These techniques may even be implemented using simple spreadsheet tool (Foo, 2019). Various water minimisation case studies based on process integration techniques have been reported for various process plants such as chemical, petrochemicals, petroleum refinery, pulp and paper mill, pulp and paper, textile, food and beverage, etc. (Foo, 2012; El-Halwagi, 2017).

References:

El-Halwagi, M. M. (2017). Sustainable Design through Process Integration. Waltham, U.S.: Elsevier.

Foo, D. C. Y. (2009). A State-of-the-art Review of Pinch Analysis Techniques for Water Network Synthesis. Industrial & Engineering Chemistry Research, 48 (11), 5125-5159.

Foo, D. C. Y. (2012). Process Integration for Resource Conservation, CRC Press, Boca Raton, Florida, US.

Foo, D. C. Y. (2019). Optimize Plant Water Use from Your Desk. Chemical Engineering Progress, 115: 45-51 (February 2019).

Gouws, J., Majozi, T., Foo, D. C. Y., Chen, C. L. and Lee, J.-Y., (2010). Water Minimisation Techniques for Batch Processes. Industrial & Engineering Chemistry Research, 49(19), 8877-8893.

Majozi, T. (2010). Batch Chemical Process Integration: Analysis, Synthesis and Optimization, Springer, London.

Smith, R. (2016). Chemical Process: Design and Integration, 2nd Ed. West Sussex, England: John Wiley.

Wang, Y. P. and Smith, R. 1994. Wastewater Minimisation. Chemical Engineering Science. 49: 981-1006.