Forward osmosis for the removal of water from a food liquid stream

Food and beverage industries often have liquid streams that require the removal of water as a preliminary step prior to storage, transportation or the ultimate production of powders such as milk, whey protein and lactose powders. Conventional methods of water removal include evaporation and drying, which are energy intensive and expensive, and not ideal for food and beverages that are heat sensitive.

Forward osmosis (FO), originally developed for water treatment, utilises the natural osmotic pressure of a concentrated saline solution, known as “drawn solution”, to “draw” water through a semipermeable membrane. If this draw solution is readily available and does not require further regeneration, FO is an attractive alternative that is less energy intensive and cheaper compared to reverse osmosis (RO) or nanofiltration (NF) that requires high hydraulic pressures.

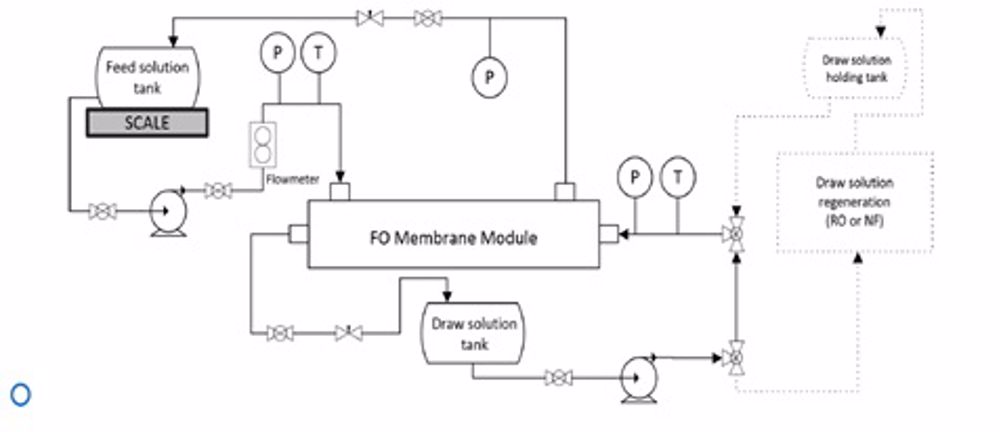

Within the Department of Chemical and Process Engineering at the University of Surrey, we have a pilot scale FO system capable of handling 250 litres of feed with a membrane area of 24m2 (see Fig 1). In collaboration with the University of Melbourne and High Weald Dairy, we have successfully carried out the world’s first pilot scale demonstration of the concentration of milk and whey using FO technology and a draw solution that mimics the potential brine streams (48–57 g/L of NaCl), available in dairy processing plants, avoiding the need for additional regeneration steps [1]. The FO technology was able to achieve a concentration factor of approximately 2.5 at an energy consumption rate of 5-10 kWh per tonne of water removed, much lower than that required by RO (9-20 kWh/t water removed) [3, 4].

The food and beverage industry is UK’s largest manufacturing sector and contributed £29billion to the UK economy in 2019 [4]. Globally the sector is worth about $6200 billion [5]. This FO technology could potentially lead to savings of millions of dollars by addressing the cost, technical and environmental challenges of water separation in food and beverage manufacturing, and allow this sector to increase in productivity and grow more sustainably. It has been very exciting and rewarding to demonstrate this potential through our very productive Australia-UK chemical engineering collaboration

[1] Chen, G. Q., et al. "A pilot scale study on the concentration of milk and whey by forward osmosis." Separation and Purification Technology 215 (2019): 652-659.

[2] Daufin, G., et al. “Recent and emerging applications of membrane processes in the food and dairy industry”, Food Bioprod. Process., 79 (2001): 89-102

[3] Brazinha, C. et al. “Integrated Membrane Operations: In the Food Production De Gruyter (2014)

[4] https://www.fdf.org.uk/fdf/business-insights-and-economics/facts-and-stats/

[5] https://www.thebusinessresearchcompany.com/report/food-and-beverages-global-market-report