Rags to Riches - Chemical Engineering in Whey Processing

"Little Miss Muffet sat on a tuffet eating her curds and whey, along came a spider, who sat down beside her and frightened Miss Muffet away"

Dairy farming and milk processing have long been a major component of the New Zealand economy; it is the largest export goods sector in New Zealand accounting for approximately one in every three dollars NZ earns [1].

Chemical engineering has long been practised to a very high level in the dairy industry [2] and has been a key component of dairy research at the NZ Dairy Research Centre (now the Fonterra Research and Development Centre) since its inception in 1927. This is well illustrated by considering whey processing in New Zealand.

Whey, the liquid remaining after the production of cheese or casein from milk, is dilute (typically 6.5% total solids) and comprises about 85% of the quantity of the original milk. In the 1960s, most whey was fed to pigs or disposed of by irrigation to land or into natural waterways. It is highly polluting (BOD 35,000mg/litre) and, if discharged in excessive quantities to waterways, causes massive growths of slimy microbial mass and depletes the water of oxygen to the detriment of the natural flora and fauna. Today in NZ all whey is processed to profitable products [3].

It is interesting to me that one of the pioneers of whey processing in NZ was Donald Sandys Wunch. He was one of the founding members of the IChemE. Wunch came to New Zealand in 1929 and became manager of what became the Lactose company. Wunsch was convinced that the lactose industry needed not chemists but chemical engineers, and as professional qualifications were not attainable in New Zealand, he trained several himself.

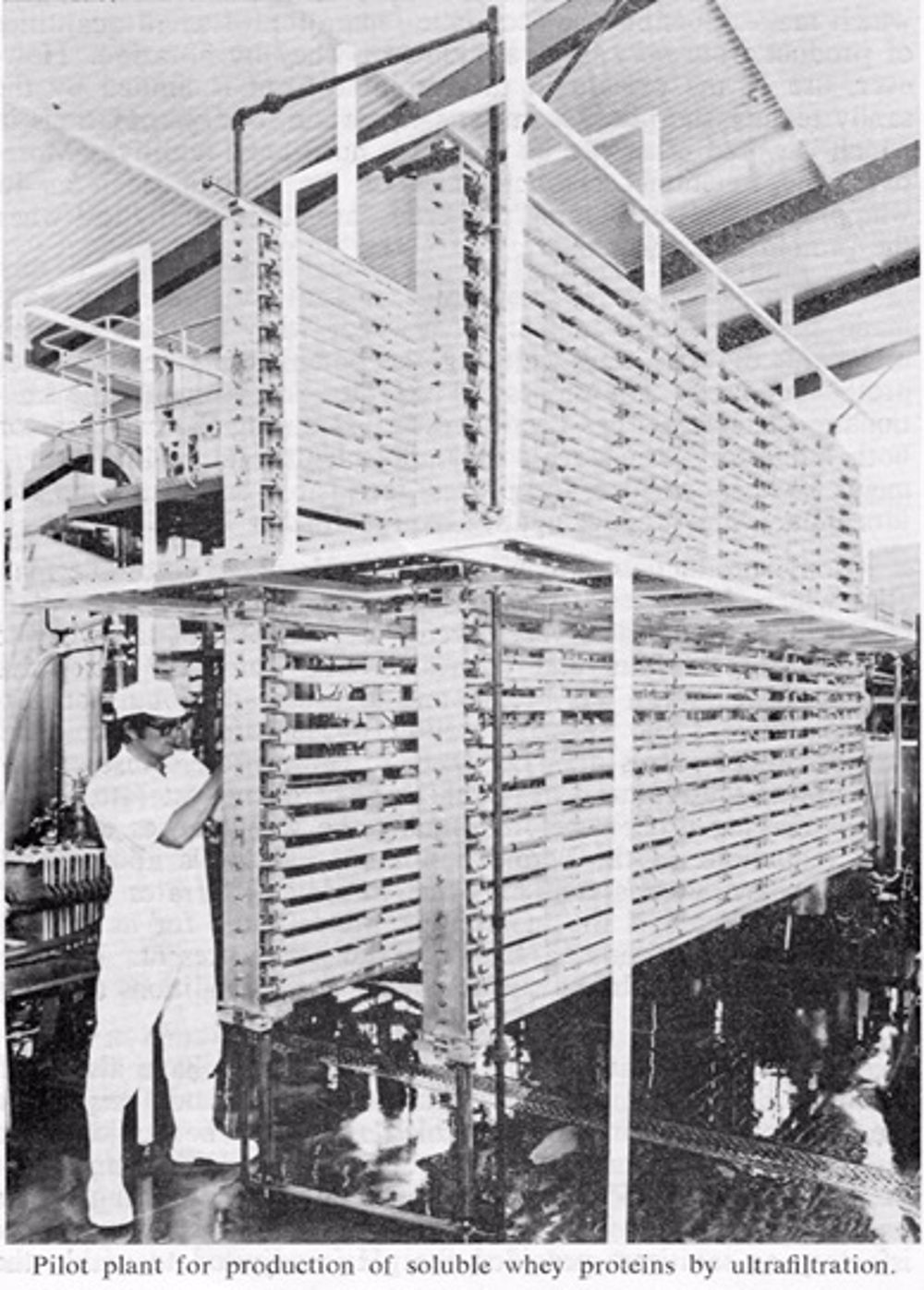

In 1969, contemporaneously at the New Zealand Dairy Research Institute and the Lactose Company, pioneering membrane (ultrafiltration and reverse osmosis) technology research was undertaken to separate the protein from whey in a soluble, nutritious form. Then no commercial technology existed for this task. I was part of a group of chemical engineers working with a cross-functional team of food technologists, scientists and marketers who researched and developed ultrafiltration processing of whey to a commercial scale. This unit operation was combined with other chemical engineering processes and unit operations (including centrifuging, filtration, evaporation, spray drying) to produce a world-first high protein whey product. The initial product was developed to satisfy the Coca-Cola Export Corporation's desire for large quantities of protein soluble in an acid, carbonated beverage. In the 1970s there was no known commercial process to produce the required soluble whey protein concentrate. Today these ingredients provide excellent nutrition and are used in a wide range of foods such as infant formulae, cheese, beverages, sports drinks, medical foods, yoghurt, coffee and tea whiteners, processed meats, and bakery goods. Membrane technologies are producing a range of products including whey protein concentrates (WPC), milk protein concentrates (MPC), cheese, protein-standardized milk powders, ethanol, and lactose.

Membrane technology has come a long way from processing effluent streams to being an essential part of the dairy industry

References:

[1] https://www.dcanz.com/about-the-nz-dairy-industry/

[2] Unit Operations in Food Processing by Prof. Dick Earle. https://www.nzifst.org.nz/page-18140

[3] https://www.nzifst.org.nz/resources/Documents/WheyToGo-print-res.pdf