Chocolate – An indulgent treat AND a fascinating engineering challenge!

Chocolate is a food that we eat for pleasure. What started as a bitter drink in Mesoamerica is now a £100 billion global market.

Chocolate is possible to make at home – but to make it at scale is an engineering process. The big companies that make chocolate; Hershey, Nestle, Mars and Mondelez (including Cadbury) all use factory processes to make chocolate, and employ many chemical engineers.

Making chocolate industrially is a complicated process – the need is to make it cheaply, safely, and at volume, so that every bar or sweet gives the consumer the same satisfaction.

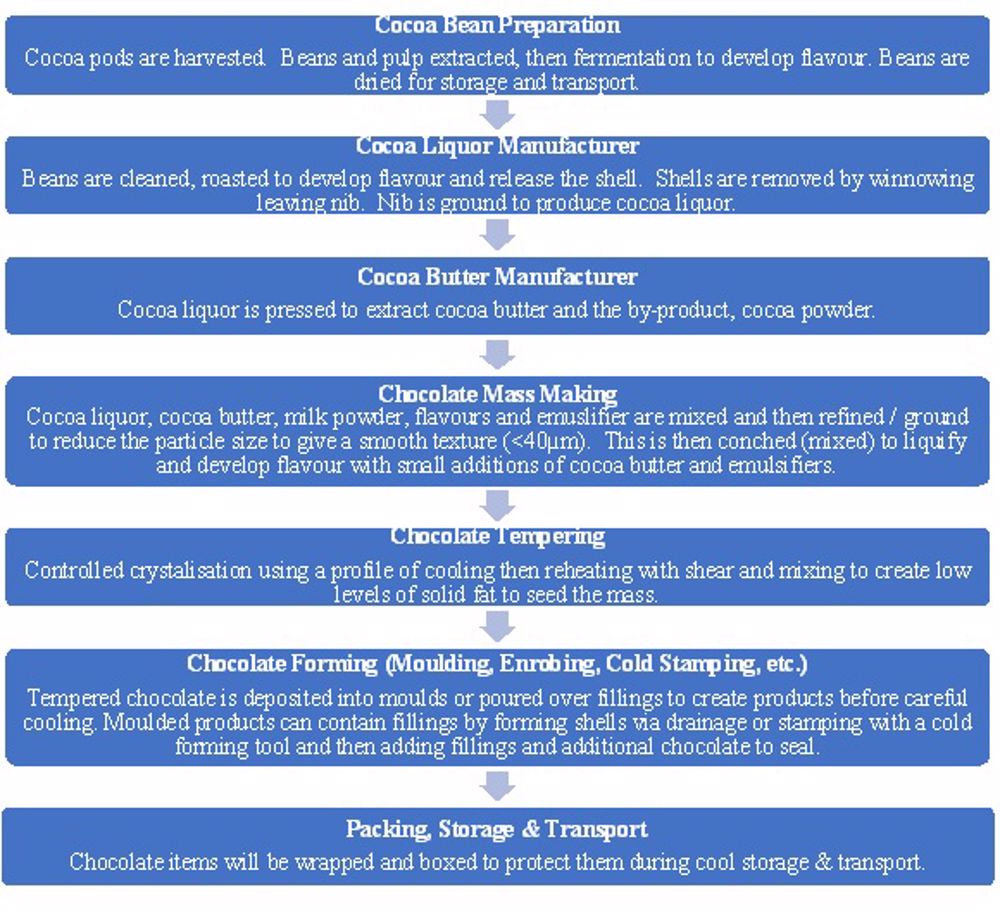

Chocolate processes vary in detail, but the core process is given in Figure 2. Cocoa beans are harvested and roasted, with the resulting materials ground and pressed to make cocoa powder and cocoa butter. The main ingredients of chocolate are cocoa butter and sugar. Adding the dark part of the cocoa bean, liquefied, and refined cocoa nib called cocoa mass or liquor, gives dark chocolate. Without the dark part, milk ingredients can be added to form white chocolate. Adding both milk ingredients and cocoa liquor gives a milk chocolate.

The next stage is the creation of chocolate mass, a uniform paste that contains mixed sugar, cocoa and milk. The milk can be supplied as powder or start as whole milk that is made into a chocolate crumb – a cooked and dried mixture of sweetened condensed milk and cocoa liquor which helps to develop flavour. In making the chocolate mass, particle size is critical for the smoothness, and the particle size is usually controlled by passing through a series of rollers. The smoothness & flavour is then controlled by conching, a process in which chocolate is mixed and heated, which changes the viscosity and develops flavour.

The chocolate is then ready to be made into products. This is a complicated process, as it is possible for the material to solidify in different ways, with different microstructures. This is due to the chemistry of the fats that constitute cocoa butter. Consumers want chocolate that looks bright and shiny, and that can be broken with a snap, and has a melting temperature low enough that it can melt in your mouth.

Cocoa fats can crystallise in a range of six crystal forms, each with its own structure and melting point. The one that the consumer likes is form V – but this is not the thermodynamically stable form, i.e. the one that would form in equilibrium with its surroundings. The manufacturing trick is to ensure that the material is correctly ‘tempered’, cooled and reheated during mixing to create a material that will solidify in the correct form on cooling. Traditional chocolate processing typically involves a slow cooling (<2°C/min) after the tempering stage, to ensure that the right form is created. This cooling traps the fat in the Form V – although it is not stable, it is sufficiently solid that the crystals cannot change form.

The liquid tempered chocolate can be moulded into bars or used to enrobe (coat) other ingredients and fillings.

Getting chocolate to the consumer is also not straightforward, if the material is heated to the melting point, during transport or storage, the chocolate can soften enough that the microstructure can change. The thermodynamically stable version forms – the material ‘blooms’ to create a chocolate that is speckled to the eye and tastes gritty, because the crystals do not now melt in the mouth. The chocolate still has the same chemical composition but is no longer as attractive to the consumer.

Chocolate manufacture is thus a complex engineering process. It involves a range of chemical engineering operations, such as heating, cooling, and mixing, that are common across different process fields. As ever, scale up is a critical issue – a new product can be developed in the design kitchen or pilot plant, but setting the process lines up to make it at volume is a difficult task. It’s very interdisciplinary - chemical engineers work with chefs and food scientists who make the products at small scale, and who ensure that the product tastes good, and the mechanical and control engineers needed to make the process equipment and ensure that it runs efficiently. Increasingly the need is to make the process sustainable, both by ensuring that the ingredients are sustainably sourced, and that the manufacturing process is zero carbon.