Brewing – more than Beer

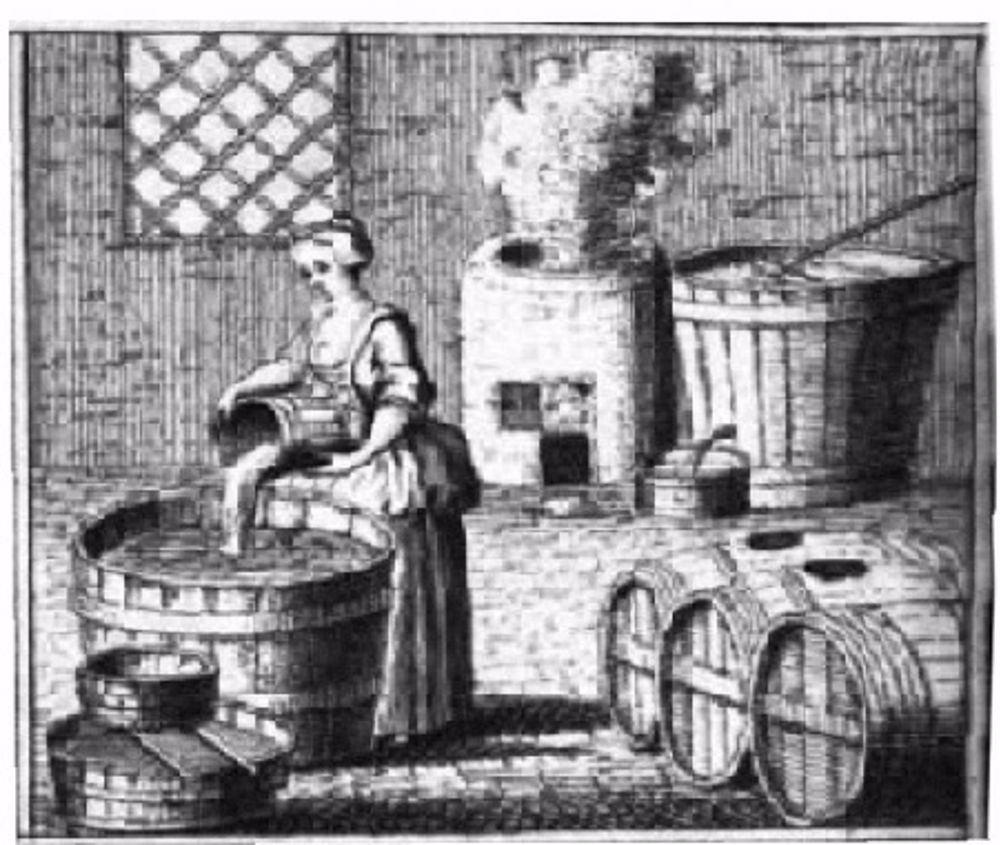

Pre industrialisation a "spinster" was a woman who spun fibres into thread at home. A "brewster" was a woman who brewed beer at home. These were domestic occupations.

It was only with industrialisation that the male occupations of "spinner" and "brewer" became common.

In the late 19th century, the very large vessels, heating and other processes under careful control in brewing were pretty much the same as ones being developed in the chemical industry. So brewing was recognised as part of chemical engineering from the earliest days of the IChemE.

Penicillin was only produced on the huge scale needed by chemical engineer Margaret Hutchinson Rousseau adapting brewing vats to suit the mould which grows on bread – actually a remarkable achievement. This deep bed fermentation is also used today for the production of citric acid from another mould, aspergillis niger. Citric acid can be obtained from fruit, but this method is equally natural, chemically identical and both much cheaper and less of a burden on the environment. Citric acid gives the bite of lemonade and is used in a variety of food and drink as well as in shampoos, eco-friendly cleaners and other products.

Vitamin C (ascorbic acid) is also produced industrially by a fermentation process, starting with sorbitol from potatoes. It is therefore not ‘artificial’ and is used in foods and drinks. Its antioxidant value helps it to be used as a non-toxic preservative in a variety of domestic products.

Brewing produces more than beer and other alcoholic drinks. It is the source of yeast used in bread and thus vital to the major food, which today involves much chemical engineering. Yeast itself is a source of commercial B vitamins and its residue after brewing is enjoyed or hated as the food spreads Marmite ™ and Vegemite ™.

These are, of course, biological processes. Many more have been developed, and biotechnology is being increasingly used by chemical engineers for their processes. For example, human insulin is now produced from genetically modified bacteria such as Escherichia coli in a fermenter. It is the human gene which is used so the product is more effective than that from animals, and does not require large scale slaughter as was previously done.

In fact, biotechnology is now in a similar position to chemical technology when the IChemE was founded, with a thorough understanding of the science and the ability to manipulate organisms to produce totally new products and processes. The practical application depends a great deal on what was learned from industrial fermentation processes in brewing, and many chemical engineers work in biotechnology.