Natural Gas

Geologist reporting to company executives on the latest exploration:

The bad news is that we did not find any oil. The good news is that we did not find any gas either.

Gas projects are costly and unlike oil, gas needs a dedicated and profitable market. Discovery to first production of gas takes between ten and fifty years and most of this time is taken by securing long term gas sales to underwrite the investment and optimising the plant design.

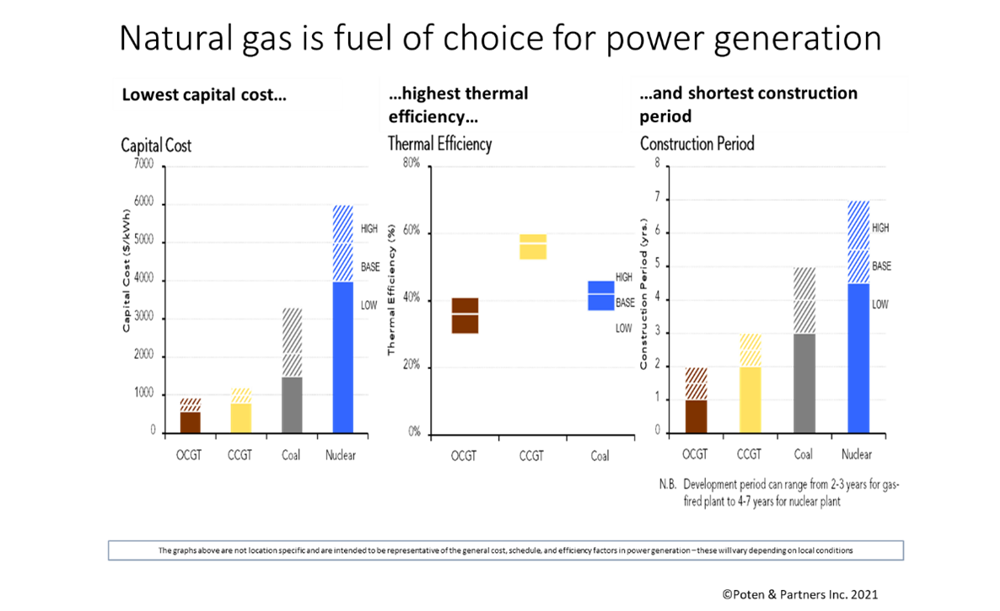

Natural gas, methane, was not seriously exploited until the 60’s but has now supplanted gas manufactured from coal in city gas systems. Combined cycle gas turbine power generation (CCGT) is the largest and growing market for gas.

Natural gas has the highest hydrogen:carbon ratio of any hydrocarbon and hence to lowest CO2 emissions. A gas fired CCGT emits about half the CO2 of a coal fired power station for the same output and is around half the capital cost. Gas is also relatively safe to handle due to its modest explosive limits and low flame speed, plus rapid dispersion of leaks due to its low density.

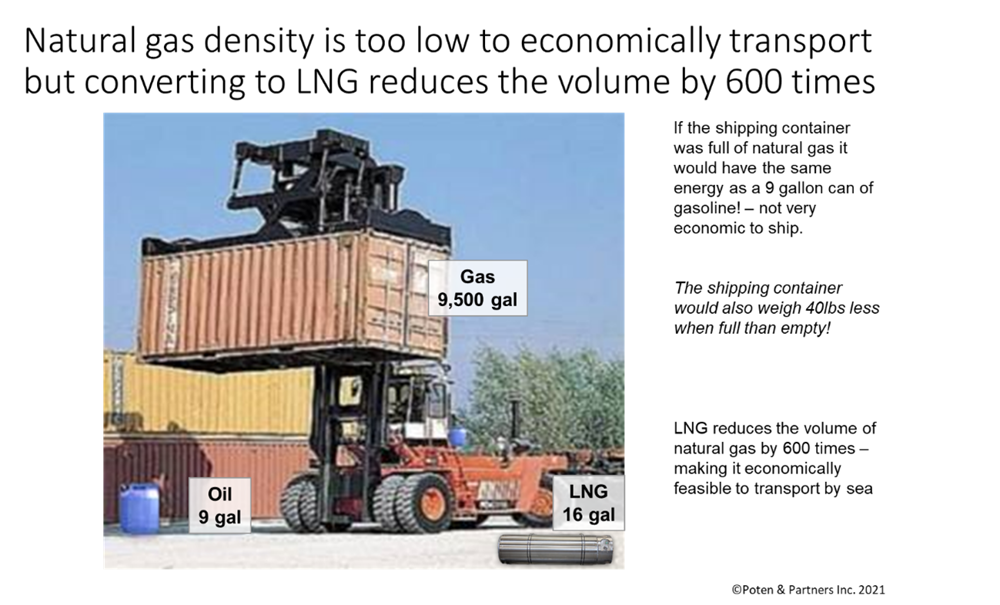

The problems with natural gas are its very low density (about one thousandth of oil) and a low triple point (it cannot keep it as a liquid at ambient temperatures). This means it is expensive to move by high pressure pipeline or as liquid natural gas (cryogenic temperatures – minus 160C).

Most conventional gas resources close to markets have probably been found and developed. The new resources are based on newer technologies, such as fracc’ing and directional drilling, and ultra-deep water.

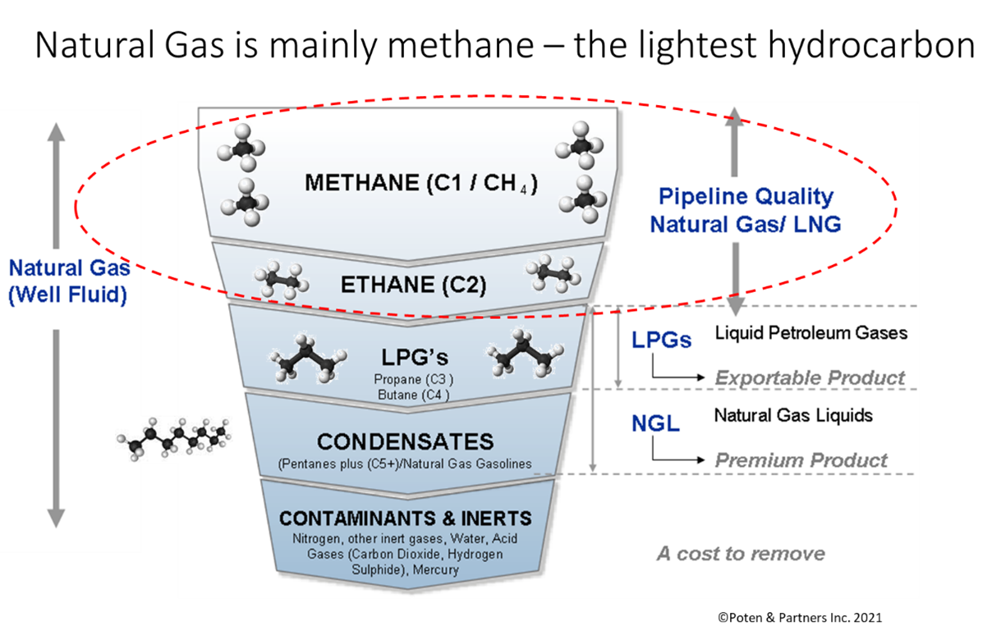

Natural gas resources can be associated with oil, condensates, LPGs (propane and butane) or relatively lean. Oil and condensates can be sufficiently valuable to make the marginal cost of gas negative and this has led to flaring. Gas usually contains contaminants such as sulphur compounds, carbon dioxide, water, nitrogen and other inert gases. These are costly to remove and Chemical Engineers are constantly challenged to design plant to remove these at least cost. The technologies developed for removing CO2 from natural gas are being proposed for use in carbon capture.

Unless close to a market, gas projects have to be ‘mega-projects’ exporting either by pipeline or liquefying. LNG (liquid natural gas) projects are the largest projects that are developed by commercial companies and range from $20 to $80 billion and only exceeded in cost by a handful of government infrastructure projects.

For the last few decades, gas use has grown and LNG grown by more than 6% / year. Countries and companies still see gas as a relatively pain free route to lower CO2 emissions by phasing out coal usage in power generation.

Chemical engineers are critical to this industry and through scale and learning curve effects have drastically lowered unit costs over the last 50 years. Engineers have also improved the economics by extending maintenance intervals and reducing turnaround times.

Methane is still a hydrocarbon and its use needs to be drastically reduced as we approach the target of Net-Zero. Leakage of natural gas is also highly undesirable as it is a potent greenhouse. At the moment, we do not have good data on the emissions of methane to atmosphere and the industry is working hard on this issue as it could be a quick win to help mitigate climate change.

Due to the challenges of managing a power grid, we may never be able to entirely eliminate the use of natural gas – we may have to retain some capacity and rely on carbon capture or mitigation for these.