Australian Chemical Engineers to the World

When I completed my chemical engineering degree at Monash University in Melbourne in 1973 there were many job opportunities in the growing oil and gas and petrochemical industry in Australia. Over the next 10 years demand for young process engineers with design experience attracted many Australian chemical engineers to the North Sea offshore developments in the big London design houses. Back in Australia opportunities were evolving for optimisation of overseas technology to best exploit the oil and gas projects on Western Australia’s north west shelf. A growing community of chemical engineers trained in Australian universities with offshore experience were soon taking advantage of boom times as the liquefied natural gas industry was born. Australians’ self-confidence, and the sound all round education in unit operations and the fundamentals of process engineering, were the catalyst for the strong growth in the engineering contracting industry in Australia from the 1970s onwards.

In 1990 with 16 years of experience as a process engineer, following graduation from Australia’s Monash University, a classmate of mine Mike Reilly, relocated to the United Kingdom for two years to gain North Sea design experience. On arrival, he accepted a position as a Senior Process Engineer with English engineering contractor Brown & Root in London on the design team for the Chevron Alba Northern Facilities. This project was just commencing detailed design. The facilities consisted of a 75,000 barrels of oil per day (BOPD) production platform with export of the waxy, high pour point crude via a 300 mm subsea pipeline to a remote Floating Storage Unit (FSU).

After 6 months on the project, Mike was promoted to lead utilities Process Engineer leading some 25 engineers during the design completion of the utilities systems. He stayed on the project until handover of the design to the owners in 1992 with responsibility for compilation of project design books which transfer the designer’s intent to the facilities operational team. In order to confirm the design basis and sizing of all project lines, Mike used the final line list to prepare a comprehensive line sizing calculation register confirming sizing calculations and selected piping were approved for construction. Brown & Root subsequently adopted this approach as part of the company’s project close out procedure, which Mike also incorporated into Australian engineering contractor Worley’s procedures when he joined them after leaving the UK. Mike’s two years’ North Sea design experience demonstrated the value Monash trained chemical engineers could deliver to jobs at the epicentre of hydrocarbon engineering at that time and was a great preparation for his role of engineering manager for the world class Bayu-Undan development designed in Australia.

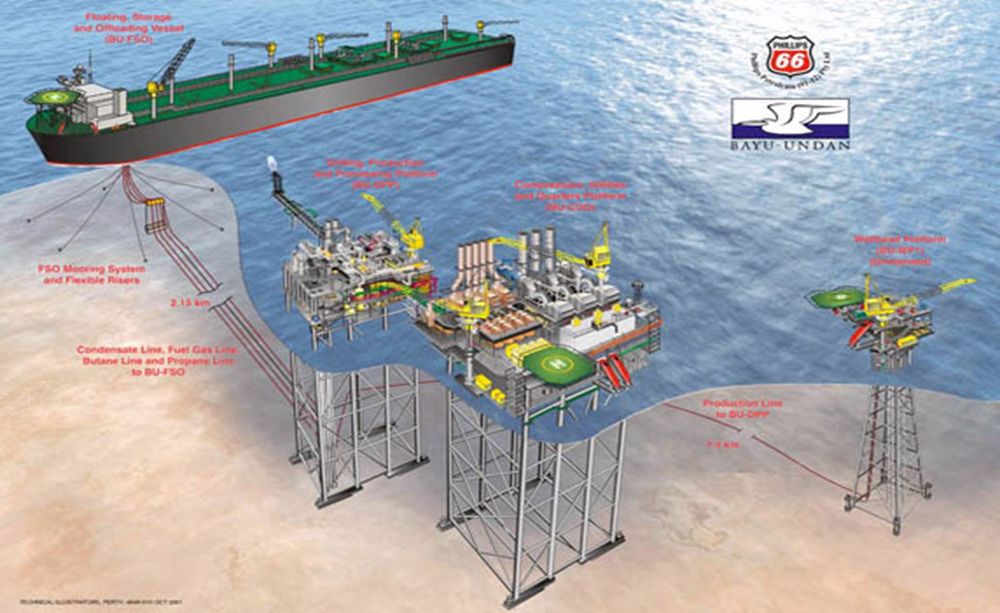

The Bayu-Undan Field is a gas/condensate field located 500km north-west of Darwin, Australia and 250km south west of Suai in Timor-Leste. Commercial production commenced in 2004 initially based on liquids export by tanker and lean gas reinjection to the reservoir, with lean gas export commencing by subsea pipeline in 2006, once the associated onshore LNG Plant near Darwin was commissioned. The Bayu-Undan offshore facilities are a world class development, and the Australian based engineering delivered many significant, world leading accomplishments, including:

- World’s first offshore distillation facilities for separation of commercial grade propane and butane.

- First refrigerated storage of LPGs on a floating storage and offloading (FSO) vessel, and

- World’s largest float-over integrated decks, at the time of installation.

The project also achieved a maximum recovery of condensate liquids from rich feed gas, by innovative turbo-expansion cooling and liquids separation from the stripped gas before lean gas reinjection/export. This technology was validated by a 4-week 3rd party laboratory based technical study under Mike’s direction in the USA to meet owner’s project approval criteria.

The facilities were commissioned without major issue and have continued to operate safely meeting design requirements.