Engineering a Healthier Society - Pharmaceuticals for all

Have you ever been ill? Have you ever broken a bone? Have you ever been to the chemist to get medicine? If so, then you have relied upon the work of Chemical Engineers working in the healthcare sector.

The pharmaceutical industry in the UK employs around 67,000 people and 25,000 of those work in research and development. Chemical engineers are employed at all levels in pharmaceutical companies including well-known multinationals.

It will be the chemical and process engineers who will provide the production process to meet the manufacturing requirements.

What is a Pharmaceutical?

Pharmaceuticals can be for use in diagnosis, cure, mitigation, or prevention of a disease.

Therapeutic products for humans and animals include chemicals such as aspirin and antibiotics, vaccines, such as influenza vaccine, biotechnology-derived medicines such human growth hormone and Humulin for the treatment of diabetes and monoclonal antibodies used for the treatment of cancer. Recent advances in cell and gene therapy are leading to effective anti-cancer drugs and corrections to genetic deficiencies. Typically, a medicine consists of two parts: the active ingredient and the other ingredients which make it into a suitable form for the patient such as a tablet.

Diagnostics are pharmaceuticals, for example Professor Zhanfeng Cui (Professor of Chemical Engineering, Oxford University) and his team in 2020 developed a rapid test for COVID-19.

What is the contribution of Chemical Engineers in Pharmaceutical manufacturing?

Chemical engineers work in multi-disciplinary teams that discover and develop products and processes. Chemical and biochemical engineers work alongside scientists, including chemists, biologists, biochemists, pharmacists and geneticists, in the development of pharmaceutical products and processes to make them. Engineers must speak the language that lies behind drug discovery and are the link between the laboratory and the manufacturing plant. Chemical engineers scale-up the manufacture to make clinical trial material and later to make the commercial quantities. As shown by the cartoon below, it is not as simple as just making a “large laboratory”. Without Chemical Engineers, there would be no way the life-saving medicines could reach the patients that need them. This has been clearly shown in the speed that the new vaccines for COVID-19 have progressed from the laboratory to manufacture, all within a year. The role out of vaccines worldwide is now underway and chemical engineers have had a significant input in making this happen.

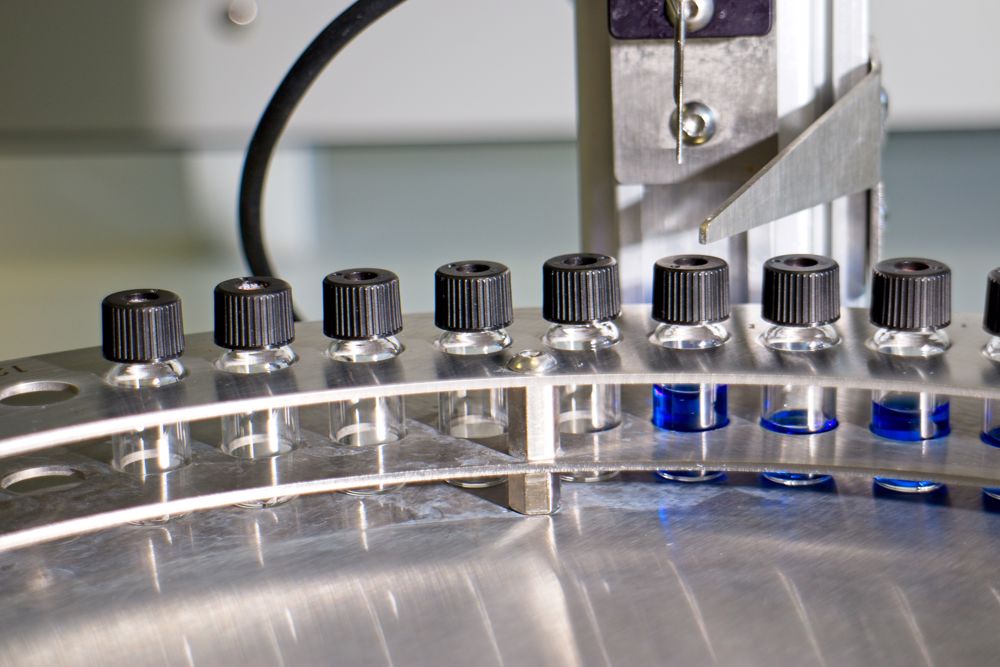

Chemical engineers also specify and design manufacturing facilities and processing equipment and the associated instrumentation and control systems. As they understand the key quality-related manufacturing factors, engineers also validate production processes to ensure that they consistently meet regulatory requirements. Without this, the medicine cannot receive the approval to be given to patients.

Pharmaceuticals are often complex and costly to make. Engineers “de-bottleneck” and ‘’process intensify’’ to improve efficiency, but also ensure the manufacture is completed safely whilst striving to reduce the environmental impact. To meet these aims, the engineer will investigate alternative manufacturing technologies in addition to optimising individual processing steps. Without this, the manufacture of a medicine would not be viable and so could never be given to patients.

The importance of continued learning

Pharmaceutical manufacture is a highly regulated environment to ensure patient safety. These regulations are set out by Good Manufacturing Practices (GMP). Examples of this are the specific quality requirements for utilities (i.e., water, steam or air used in the process and not only covers generation but also the distribution through the facility), materials of construction, analytical testing and many more. If these aspects are wrong, the quality of the final pharmaceutical could be impacted and in the worst case a patient will become infected.

Chemical Engineers within the pharmaceutical industry can meet like minded engineers through the Pharma and Biochemical Engineering special interest groups.

Key Chemical Engineers in Pharmaceutical manufacture

Examples of chemical engineers having a significant impact in the production of pharmaceuticals are.

- Margaret Hutchinson Rousseau- designed the first commercial penicillin plant using deep tank fermentation

- George Rosenkranz- developed the first two combined oral contraceptive pill

- Robert Langer- pioneered a new drug delivery system using transdermal delivery

Conclusion

Chemical engineers contribute to a healthier society in development, designing and operating plants at the scale required both economically and meeting environmental requirements. Without chemical engineers, the health of billions of people worldwide would be worse.