Chemical Engineers and the Environment

The modern profession of chemical engineering and the IChemE quite literally began from a concern for the environment.

The 1864 Alkali Act, the first environmental legislation in the UK was set up to limit acid fumes from chemical plants. The Leblanc process produced nearly 0.7 tonnes of HCl (hydrochloric acid) for every tonne of its product Na2CO3 (sodium carbonate), and initially this was just released to the atmosphere.

The Act required 95% to be captured.

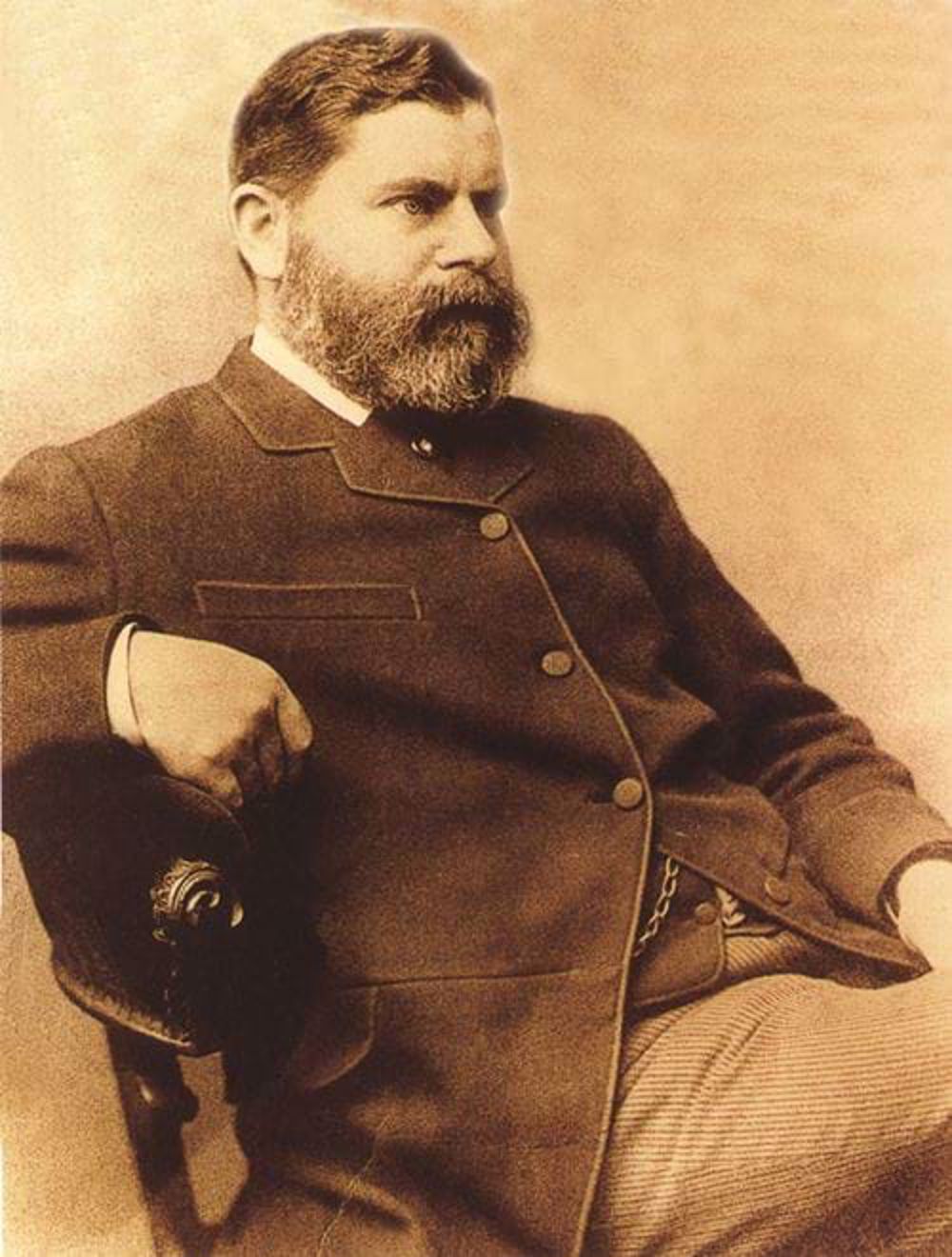

One of the first inspectors to police this was an experienced industrial chemist (as he was called then) named George Davis. After ten years inspecting many types of chemical process, he was shocked by the inefficiency and waste of so many of them. He and his brother set up a consultancy to advise industry on how to do better. As one biographer remarked: “Most of his inventions and processes arise from his intense disgust with the methods of manufacture which polluted the air, rivers and watercourses and wasted good land for tips.”

George Davis gave the first lectures on chemical engineering and published the first Handbook of Chemical engineering, which led to chemical engineering as a discipline and the formation of both the AIChE (American Institute of Chemical Engineers) and IChemE.

Careful use of materials and minimization of waste is ingrained in chemical engineers from the beginning. A key tool is the mass and energy balance of all the chemical and transport processes in a plant within a diagram called a flowsheet. Chemical equations must be balanced, thermodynamic changes calculated, heat and material in and out carefully measured. Nothing must be missed out. In addition, recycling is a key skill. These are not afterthoughts, but part of the basic design. Chemical engineers can often improve other processes by applying their skills and mathematical tools and have been in demand for many industries as environmental regulations become stricter.

Many factories have what is in effect a chemical plant making sure their effluent and emissions to atmosphere meet or exceed legal requirements.

The mass and energy balance and the process flowsheet familiar to chemical engineers is not limited to chemical plants. It can be applied to many production processes such as food or the preparation of household goods like shampoo or paint. Protection of the environment is equally important in these areas where chemical engineers work.

It can also be applied on a larger scale to movement and chemical changes in the environment, and many chemical engineers work on this scale as environmental engineers for companies, national agencies, and research units. They will be a vital part of bringing the planet back to a more sustainable and comfortable condition for us.